Optimarin AS was founded in 1994 in Stavanger, a town along the west coast of Norway and we were one of the first companies in the world to develop a system for environmentally friendly purification of ballast water.

Although we recognized that there were various methods for purifying ballast water, both chemical and environmentally friendly methods, we chose to pursue a solution that does not use any chemicals and leaves no residual products that are harmful to the ocean or the environment. In the year of 2000 we were honored by installing the world’s first ballast water treatment system on board the cruise ship Regal Princess.

After several years of testing, developing and patenting new technology, we finally obtained type approval for the Optimarin Ballast System in 2009, in accordance with Guideline 8 and the ‘International Convention for the Control and Management of Ships’ Ballast Water and Sediments, 2004’. The Optimarin Ballast System (OBS) uses approved technology that significantly exceeds the stringent requirements set out in the IMO Convention. But for Optimarin, it is not enough to simply be approved. We operate in accordance with ISO 9001 / 2008 and our vision is to have the most environmentally friendly ballast water purification system in the world.

At our main office in Sandnes we have a fully operational Optimarin Ballast System test facility which may be used for training of customer’s technical personnel, or for internal R&D purposes.

Our Logistics department has established a main warehouse facility strategically placed in Europe, in Luxemburg – with excellent connections to airports, shipping ports and land based transportation of our products on their way to our customers all over the world.

Optimarin Ballast System

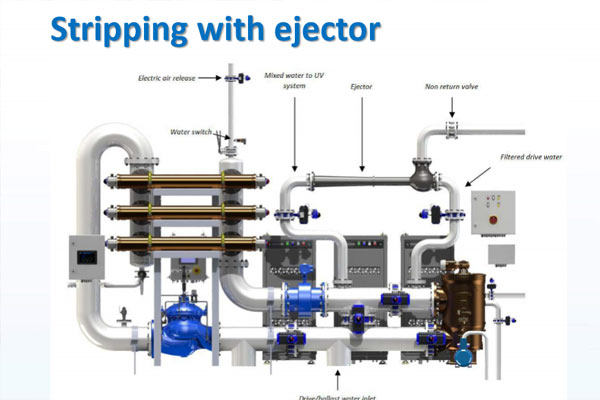

The type approved Optimarin Ballast System is based on filtration as pre-treatment and high doses of UV irradiation for inactivation of marine organisms, viruses and bacteria, without affecting the normal operation of the ship. Ballast water is UV treated both during ballasting and de-ballasting to ensure the dual UV effect. Ballast water is only filtered during ballasting.

The OBS is one of very few treatment options that does not use or generate chemicals or biocides in its treatment or cleaning processes. It is based on the idea that such systems should be environmentally sound, simple, flexible and easy to install, and capable of operating on both newbuilds and existing vessels.

The OBS is certified to operate in all salinities. (freshwater, brackish and seawater)

The Optimarin Ballast System is easy to install on board existing ships (retrofit) as well as on newbuilds. The modulized system is very flexible, with a relatively small footprint and weight, and will fit vessels of all kinds and sizes. The OBS can be delivered as a complete skid or as a customized solution. It accommodates a wide range of ballast water capacities and can handle flows up to 3.000 m³/h (or higher upon request).

Optimarin’s endeavours have also assured approval from a range of classification organizations, including Lloyd’s Register, Germanischer Lloyd, Bureau Veritas, MLIT Japan, Russian Maritime Register of Shipping and American Bureau of Shipping.

The Optimarin Ballast System is normally installed in the pump or engine room and in close proximity to the ballast pumps. The OBS can be delivered in a container, on a skid or in separate pieces to allow for easy installation in most any available space. The equipment can be installed horizontally, vertically, on or suspended below deck, along the ship’s side or in several separate locations. It is relatively low weight and adds no extra noise. The OBS utilizes every square meter and does not require much space, this makes it a cost-efficient solution.

UV System

The UV System was developed based on 20 years of experience in water injection on offshore platforms, water treatment for fish farming and drinking water plants in Norway.

☑ One UV lamp per chamber (167 m3/h flow rate per chamber).

☑ Standardized UV chamber, installed in parallel on a single manifold for higher flows.

☑ Optimized for minimum maintenance and ease of operation.

☑ Self-cleaning, with no moving parts or need for chemical cleaning.

☑ UV and temperature sensor in each chamber.

Filters

Optimarin offers three different 40 micron filters:

☑ FilterSafe basket type.

☑ B&K candle type.

☑ Filtrex basket type filter.

With our range of filters Optimarin can offer:

☑ Automatic back flushing and self-cleaning.

☑ Removal of large particles and organisms.

☑ Low pressure loss of only 0.1 – 0.5 BAR.

☑ Horizontal or vertical installation.

☑ Bypassed during de-ballasting.

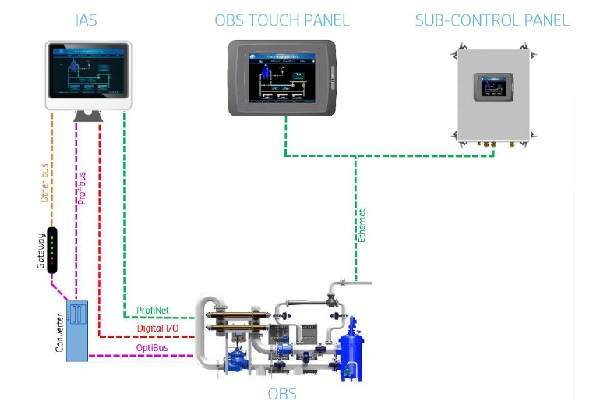

Control System

The Ballast Control System allows easy operation of the Optimarin Ballast System:

☑ User-friendly interface with touch screen.

☑ Easy operation: on click only to start any operations.

☑ Interface with the ship’s integrated automation system.

☑ Logging in accordance with IMO requirements.

☑ Option of receiving signals from ballast pumps and valves.

☑ Additional features as PMS integration, GPS logging and UV redundancy.

IMO

GLOBAL IMO STANDARDS

The International Convention for the Control and Management of Ships Ballast Water & Sediments was adopted by Diplomatic Conference at IMO in London, February 2004.

STATUS RATIFICATION BWMC

In order for the Ballast Water Management Convention to enter into force it is required that 30 flag states, representing at least 35% of the world fleet tonnage ratifies the convention.

By April 2016, 51 states have ratified. This provides a total of 34.87% of the world’s merchant fleet tonnage www.imo.org (Status of conventions)

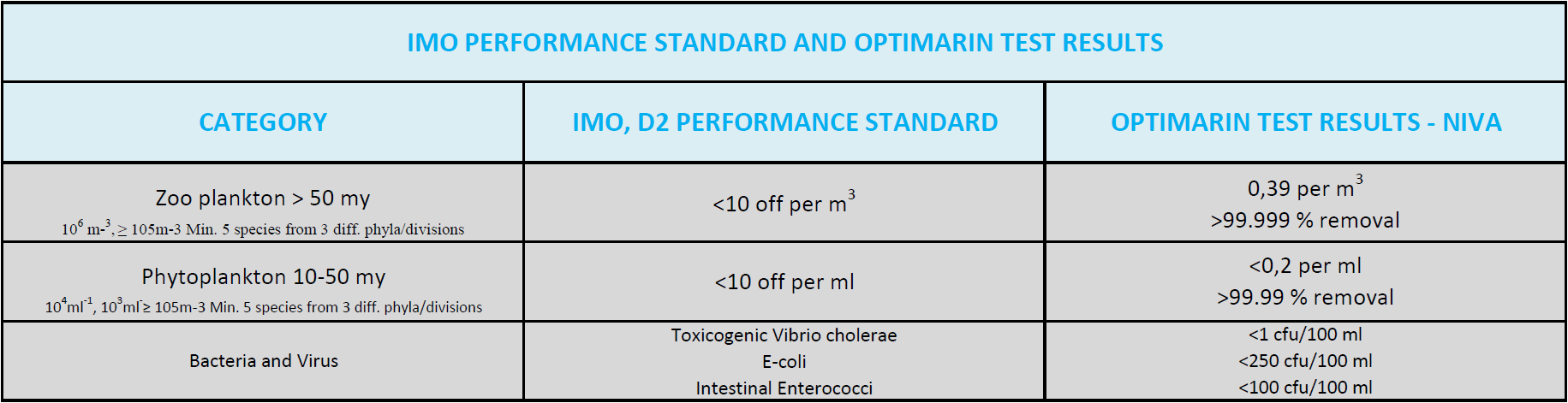

PERFORMANCE STANDARD

Regulation D2 Ballast Water Performance Standard

1 Ships conducting Ballast Water Management in accordance with this regulation shall discharge less than 10 viable organisms per cubic metre greater than or equal to 50 micrometres in minimum dimension and less than 10 viable organisms per milliliter less than 50 micrometres in minimum dimension and greater than or equal to 10 micrometres in minimum dimension; and discharge of the indicator microbes shall not exceed the specified concentrations described in paragraph 2.

2 Indicator microbes, as a human health standard, shall include:

1 Toxicogenic Vibrio cholerae (O1 and O139) with less than 1 colony forming unit (cfu) per 100 milliliters or less than 1 cfu per 1 gram (wet weight) zooplankton samples

2 Escherichia coli less than 250 cfu per 100 milliliters;

3 Intestinal Enterococci less than 100 cfu per 100 milliliters.

US Coast Guard

In March 2012 the US Coast Guard published its final rule on Ballast Water Management for Control of Nonindigenous Species in Waters of the United States. And in June the same year the USCG Regulations 33 CFR Part 151 and 46 CFR Part 162 entered into force on 21 June 2012, which apply to new builds constructed on or after 1st December 2013 as well as to existing ships by their first dry-docking after 2014 or 2016 depending on the ballast water capacity.

In order to address the US implementation schedule for ballast water treatment systems for dates prior to 2015, the USCG introduced the Alternate Management System (AMS) acceptance for some IMO approved systems including Optimarin. Ships with systems accepted as AMS installed will be grandfathered for five years beyond their USCG compliance date.

Regarding treatment The USCG requirement of BWT is instant death after treatment using a test/counting method called CMFDA which is a staining method which can determine that the organisms are really dead immediately after treatment.

The non-viability standard (acceptable under the IMO regime) which render the organism non-viable after treatment or dead after a grow-out period of 14-20 days. This test method is called MPM and is not approved by the USCG. USCG has a project to analyse the MPM method but it does not look like they will allow this it any time soon.

If USCG however do decide to change the test methods, it is a process that requires public hearing and public comments and submittal of the revised regulation through the proper US regulatory process and may take years to carry through.

Invasive Species

ENVIRONMENTAL ISSUES

The introduction of invasive marine species into new environments by ships’ ballast water, attached to ships’ hulls and via other vectors has been identified as one of the four greatest threats to the world’s oceans. The other three are land-based sources of marine pollution, overexploitation of living marine resources and physical alteration/destruction of marine habitat.

Shipping moves over 80% of the world’s commodities and transfers approximately 3 to 5 billion tonnes of ballast water internationally each year. A similar volume may also be transferred domestically within countries and regions each year. Ballast water is absolutely essential to the safe and efficient operation of modern shipping, providing balance and stability to un-laden ships. However, it may also pose a serious ecological, economic and health threat.

A potentially serious environmental problem arises when this ballast water contains marine life.

There are thousands of marine species that may be carried in ships’ ballast water. These include bacteria and other microbes, small invertebrates and the eggs, cysts and larvae of various species. The problem is compounded by the fact that virtually all marine species have life cycles that include a planktonic stage or stages. Even species in which the adults are unlikely to be taken on in ballast water, because they are too large or live attached to the seabed, may be transferred in ballast during their planktonic phase. Over the past millennia, marine species have dispersed throughout the oceans by natural means, carried on currents and attached to floating logs and debris. Natural barriers, such as temperature and land masses, have prevented many species from dispersing into certain areas. This has resulted in the natural patterns of biogeography observed in the oceans today. In particular, the pan-global tropical zone has separated the northern and southern temperate and cold water zones. This has allowed many species to evolve quite independently in these latter zones, resulting in quite different marine biodiversity between the north and the south. In tropical areas species have not faced the same barriers. This is exemplified by the relatively homogenous marine biodiversity spanning the huge area of the Indo-Pacific, from the east coast of Africa to the west coast of South America.

Humans have aided this process for as long as they have sailed, mainly by dispersing marine species that have attached to the hulls of vessels. The commencement of the use of water as ballast, and the development of larger, faster ships completing their voyages in ever shorter times, combined with rapidly increasing world trade, means that the natural barriers to the dispersal of species across the oceans are being reduced. In particular, ships provide a way for temperate marine species to pierce the tropical zones, and some of the most spectacular introductions have involved northern temperate species invading southern temperate waters, and vice versa.

It is estimated that at least 7,000 different species are being carried in ships’ ballast tanks around the world. The vast majority of marine species carried in ballast water do not survive the journey, as the ballasting and deballasting cycle and the environment inside ballast tanks can be quite hostile to organism survival. Even for those that do survive a voyage and are discharged, the chances of surviving in the new environmental conditions, including predation by and/or competition from native species, are further reduced. However, when all factors are favourable, an introduced species survive to establish a reproductive population in the host environment, it may become invasive, out-competing native species and multiplying into pest proportions.

As a result, whole ecosystems are being changed. In the USA, the European Zebra Mussel has infested over 40% of internal waterways and may have required between US$750 million and US$1 billion in expenditure on control measures between 1989 and 2000. In southern Australia, the Asian kelp is invading new areas rapidly, displacing the native seabed communities. In the Black Sea, the filter-feeding North American jellyfish Mnemiopsis leidyi has on occasion reached densities of 1kg of biomass per m2. It has depleted native plankton stocks to such an extent that it has contributed to the collapse of entire Black Sea commercial fisheries. In several countries, introduced, microscopic, ‘red-tide’ algae (toxic dinoflagellates) have been absorbed by filter-feeding shellfish, such as oysters. When eaten by humans, these contaminated shellfish can cause paralysis and even death. There are hundreds of other examples of catastrophic introductions around the world, causing severe human health, economic and/or ecological impacts in their host environments.

Invasive marine species are one of the four greatest threats to the world’s oceans! Unlike other forms of marine pollution, such as oil spills, where ameliorative action can be taken and from which the environment will eventually recover, the impacts of invasive marine species are most often irreversible! The UN considers the introduction of non-indigenous oceanic species to be one of the top four serious threats to the global environment. At any given time, 35 000 ships are en route on the water of the Earth and more than 3000 species are being transported in their ballast tanks. The UN’s International Maritime Organization estimates that ten billion tons of ballast water is transported around the world every year. The past decade has seen a marked increase in the spread of species to areas where they do not naturally belong. This creates an imbalance in ecosystems and is a serious environmental threat. Many times the invader has no natural predator and the original species become extinct and the entire marine ecosystem is disrupted. This has dramatic consequences for biodiversity and for industries such as fishing and aquaculture.

OBS Test Results

The test results are well within the requirements.

Optimarin Approvals

After several years of testing, developing and patenting new technology, Optimarin finally obtained type approval for its purification system in 2009 in accordance with Guideline 8 and the International Convention for the Control and Management of Ship’s Ballast Water and Sediments, 2004. The Optimarin Ballast System uses approved technology that significantly exceeds the stringent requirements set out in the IMO Convention. But for Optimarin it is not enough to simply be approved. We operate in accordance with NS-EN ISO 9001:2008 & 14001:2004. And our vision is to have the most environmentally friendly ballast water purification system in the world.

IMO’s regulations contain requirements that aproved systems shall not constitute a hazard to personell, the environment, the ship, or cause uncontrolled discharges. The system safeguards the people who handle it, and monitors itself to ensure that it is operating properly.

Optimarin’s type approval certificate was issued by DNV on behalf of the Norwegian Maritime Directorate. Based on the information reviewed Optimarin has also been assessed by the California State Land Commission, which stated that Optimarin has the potential to meet their standard for Best Available Technologies.

The OBS has been extensively tested at the Norwegian Institute for Water Research (NIVA) in accordance with IMO’s G8 Guidelines – with excellent results.

Optimarin’s endeavours have also assured approval from a range of classification organizations, including Lloyd’s Register, Germanischer Lloyd, Bureau Veritas, MLIT Japan, Russian Maritime Register of Shipping and American Bureau of Shipping.

Certificates of approval :

Owners

Yards

Copyright © 2024 Kavosh Abzar Aria Ltd. - All rights reserved.